| Grade | NX601 | NX602 | NX603 | NX604 | NX605 |

| Grain Size (≤μm) | 25 | 25 | 25 | 25 | 25 |

| Bulk Density (≥g/cm3) | 1.55 | 1.72 | 1.80 | 1.85 | 1.90 |

| Compressive Strength(≥MPa) | 35 | 45 | 60 | 65 | 70 |

| Flexural Strength(≥MPa) | 15 | 20 | 30 | 33 | 35 |

| Porosity (≤%) | 23 | 20 | 17 | 14 | 11 |

| Specific Resistance(≤μΩm) | 12 | 12 | 12 | 12 | 12 |

| Ash Content (≤%) | 0.08 | 0.07 | 0.06 | 0.05 | 0.03 |

| Shore Hardness | 35 | 45 | 50 | 55 | 60 |

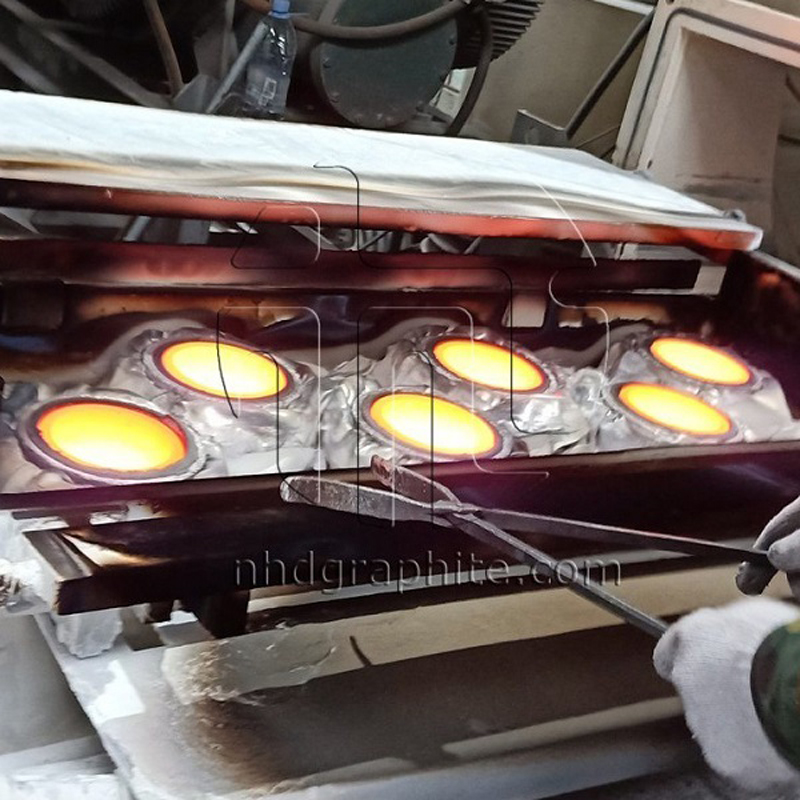

Graphite crucible for Aluminum Vacuum Evaporation Coating

Looking for a high-quality graphite crucible for aluminum vacuum evaporation coating? Look no further than our factory! We offer top-notch products and excellent service.

Request a QuotePRODUCTS DETAILS

Hot Products

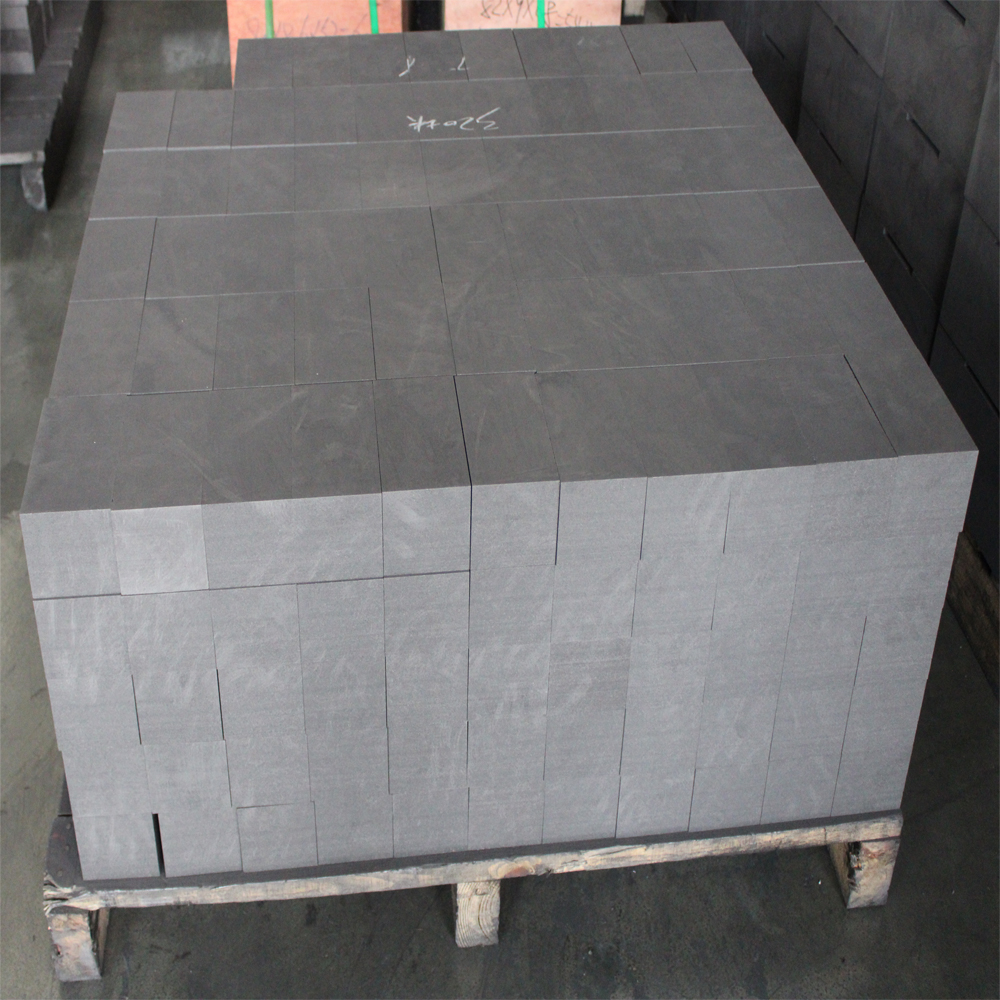

Machined graphite block for processing exothermic welding graphite mold

Extruded graphite block for exothermic welding

Molded Graphite

Graphite cave casting mould for gold sliver bar

Graphite boat graphite plate for tunsgten carbide sintering

Graphite crucible for Aluminum Vacuum Evaporation Coating

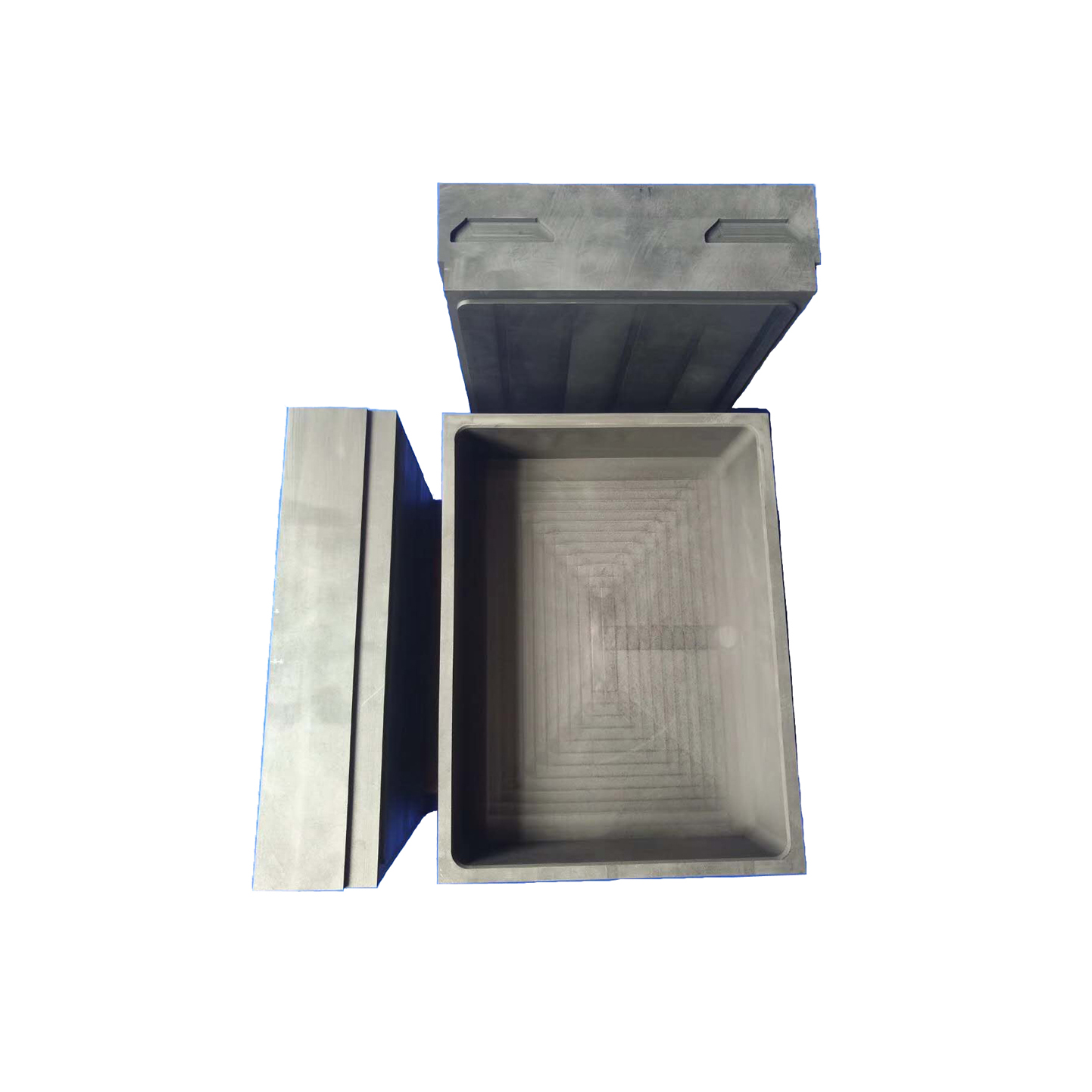

Graphite Box for anode powder

Square graphite boat

Graphite Rotor

Graphite crucible

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours