Innovative Graphite Technology Revolutionizes Sintering Mould for Industry Applications

By:Admin

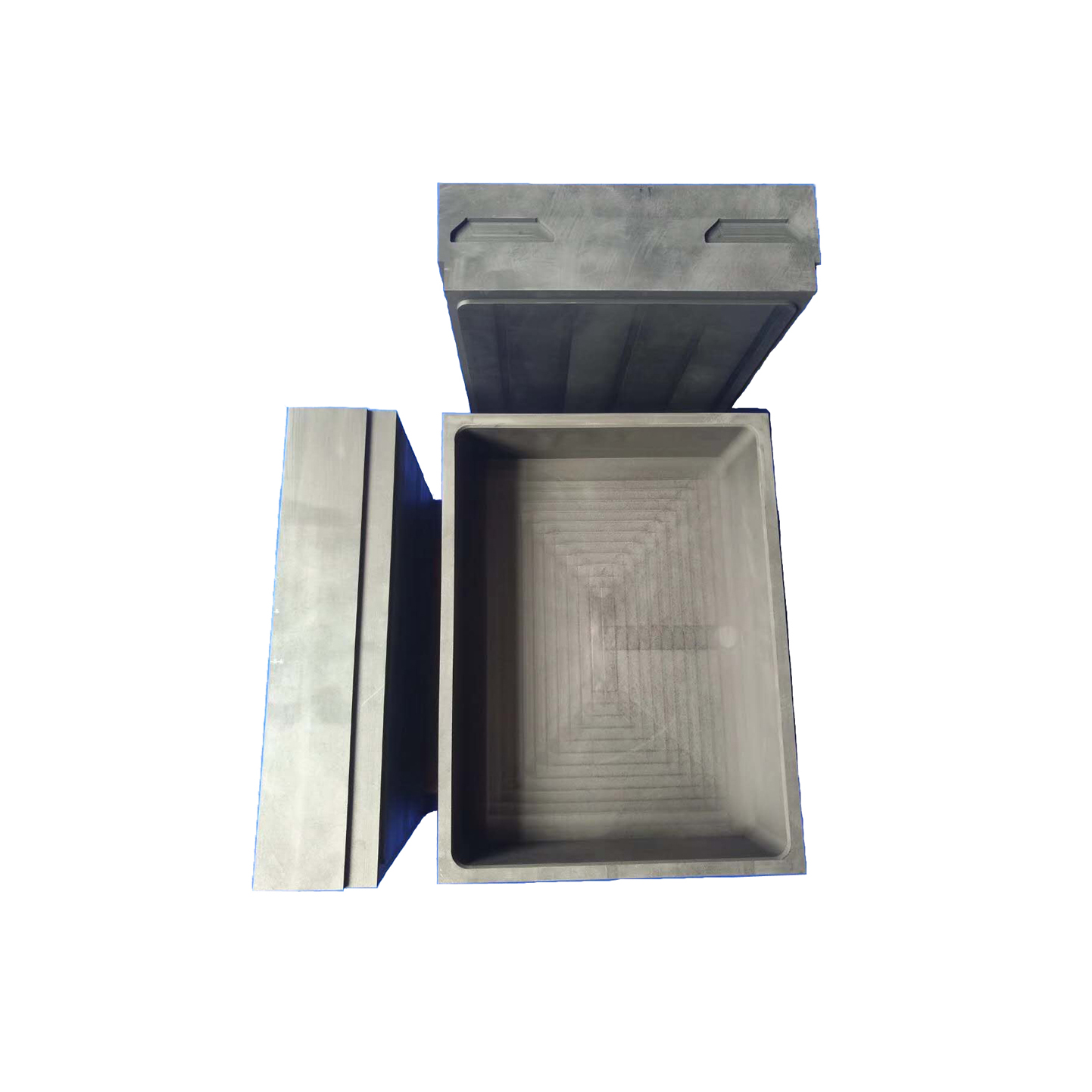

(Graphite Company Name), a leading innovator in the field of advanced materials and manufacturer of cutting-edge graphite products, has recently introduced a groundbreaking new product - Graphite Sintering Moulds. These molds are set to revolutionize manufacturing processes across various industries, providing enhanced durability, heat resistance, and improved production efficiency.

(Graphite Company Name) has been at the forefront of graphite-based innovations for over a decade, catering to the needs of industries such as automotive, aerospace, electronics, and more. With a dedicated research and development team, their focus has always been on developing advanced materials that push the boundaries of what is possible.

The recently launched Graphite Sintering Moulds are the latest addition to (Graphite Company Name)'s extensive product portfolio. Traditionally, manufacturing processes involving high temperatures and pressure require molds that can withstand these extreme conditions. This is where Graphite Sintering Moulds come into play.

One of the key advantages of these molds is their exceptional durability. Graphite, already known for its strength and resilience, has been further optimized in the development of these molds to withstand extreme heat conditions. This means that manufacturers can now produce high-quality, complex components without having to constantly worry about mold degradation due to high temperatures.

Furthermore, the heat resistance of Graphite Sintering Moulds significantly reduces the cooling time required during the manufacturing process. The molds dissipate heat quickly and evenly, allowing for a rapid cooling process. This translates into increased production efficiency as manufacturers can achieve shorter cycle times, ultimately leading to higher productivity and reduced costs.

In addition to their durability and heat resistance, these molds also offer excellent thermal conductivity. This unique property allows for more uniform heat distribution, resulting in consistent product quality and minimal defects. Manufacturers can rely on Graphite Sintering Moulds to deliver precise and reliable results, meeting the stringent requirements of various industries.

Another notable advantage of Graphite Sintering Moulds is their versatility. These molds can be used in a wide range of manufacturing processes, including powder metallurgy, metal injection molding, and ceramic sintering. They have proven to be particularly effective in industries where the production of intricate and delicate components is required. The use of these molds enables precise replication of complex designs, ensuring consistent quality across batches.

(Graphite Company Name)'s commitment to sustainability is also reflected in the development of these molds. Graphite is a naturally occurring mineral, and by utilizing it in manufacturing processes, the company minimizes the environmental impact associated with conventional mold materials. Additionally, the long lifespan of Graphite Sintering Moulds reduces the need for frequent replacements, further reducing waste generation.

To cater to the diverse needs of their clients, (Graphite Company Name) offers customization options for their Graphite Sintering Moulds. The molds can be tailored to specific requirements, including sizes, shapes, and surface finishes. This flexibility allows manufacturers to optimize their production processes and achieve superior end-products.

Overall, the introduction of Graphite Sintering Moulds represents a significant advancement in manufacturing technology. By providing exceptional durability, heat resistance, and thermal conductivity, these molds empower manufacturers to improve production efficiency and achieve consistent product quality. With their commitment to innovation and sustainability, (Graphite Company Name) continues to set new industry standards, driving progress and revolutionizing manufacturing processes across various sectors.

Company News & Blog

Isostatic Graphite Industry: Growth, Usage, and Properties – Global & China Insights, 2018-2022

Isostatic graphite: The specialty graphite with exceptional propertiesIsostatic graphite, also known as molded graphite, is a type of high-end specialty graphite that has multiple exceptional properties. It differs from other types of graphite, as it is produced by isostatic pressing of graphite particles instead of the traditional extrusion or compression processes.The resulting material has a unique microstructure that gives it unmatched mechanical strength, high thermal conductivity, low thermal expansion coefficient, excellent electrical conductivity, and chemical inertness. Therefore, isostatic graphite has numerous applications across different industries, such as aerospace, semiconductor, nuclear, and metallurgy, among others.China is one of the leading producers and consumers of isostatic graphite, with a significant increase in demand over the last few years. The country has abundant graphite resources and advanced technologies to produce high-quality isostatic graphite, which is widely used for manufacturing graphite electrodes, crucibles, molds, and heating elements.China Isostatic Graphite Pot: The Innovative Solution for High-Temperature ApplicationsThe China Isostatic Graphite Pot is a new and innovative product that is made from high-quality isostatic graphite and has excellent performance in high-temperature applications. The pot is specially designed to withstand extreme temperatures and harsh chemical environments, making it the perfect solution for various industrial processes.One of the main advantages of the China Isostatic Graphite Pot is its ability to resist thermal shock and oxidation, which is critical in applications involving the melting and casting of metals and alloys. Its superior thermal stability also means that it can maintain its structural integrity and dimensional accuracy over a wide range of temperatures, even up to 3000°C.Moreover, the China Isostatic Graphite Pot has a low porosity and high density, which enables it to have excellent mechanical strength and wear resistance. It is also chemically inert, ensuring that it does not contaminate the molten metal or alloy during the casting process.Applications of China Isostatic Graphite PotThe China Isostatic Graphite Pot has numerous applications in different industries, including:1. Metallurgy: The pot is used for melting and casting various metals and alloys, such as steel, iron, copper, aluminum, and titanium, among others.2. Semiconductor: The pot is used for growing single crystals of silicon and other semiconductors, which are used in electronic devices.3. Aerospace: The pot is used for manufacturing rocket nozzles, heat shields, and other components that require high-temperature resistance.4. Chemical: The pot is used for carrying out chemical reactions that involve high temperatures and harsh chemicals.ConclusionIsostatic graphite is a unique and valuable material that has numerous applications across different industries. The China Isostatic Graphite Pot is a new and innovative solution that offers exceptional performance in high-temperature applications, especially in the metallurgy, semiconductor, aerospace, and chemical industries. With its superior thermal stability, mechanical strength, and chemical inertness, the China Isostatic Graphite Pot is an excellent investment for any industrial process that requires high-temperature resistance and dimensional accuracy.

High-Quality Graphite for EDM Machining - Shop with Confidence on eBay

EDM Graphite: Your Partner for High-Precision MachiningWhen it comes to precision machining, EDM graphite has become an increasingly popular material of choice for both small and large manufacturers. EDM (Electrical Discharge Machining) graphite is a unique form of synthetic graphite that is used to manufacture electrodes and other components that are essential to the process of electrically conductive machining.EDM graphite is known to exhibit excellent thermal conductivity, high resistance to wear, and superior hardness characteristics. It is also non-porous and has a high resistance to corrosion, making it ideal for use in a wide range of industrial applications.Advantages of EDM GraphiteOne of the primary benefits of using EDM graphite in high-precision machining processes is its ability to deliver superior machining accuracy. Its unique composition allows it to conduct heat away from the point of contact and maintain dimensional stability during extended machining processes.EDM graphite also offers superior electrical conductivity, which enables the user to produce highly complex geometries and intricate shapes with unmatched precision.Another significant advantage of EDM graphite is its ability to support high-speed machining processes. EDM graphite can maintain its structural integrity even under high-speed machining conditions, which reduces machining time and improves overall productivity.Applications of EDM GraphiteEDM graphite is widely used in various industries, including aerospace, defense, automotive, and medical.In the aerospace industry, EDM graphite is used to manufacture components such as turbines, engine parts, and wing components with fine tolerances and complex geometries.The defense industry also leverages EDM graphite to produce intricate parts for radar systems, guided missiles, and various other electronic components.In the automotive industry, EDM graphite is widely used to fabricate mold cavities for various car parts such as dashboard panels, door handles, and other critical components.The medical industry also relies on EDM graphite for the production of precise surgical instruments and implants that require strict manufacturing tolerances.ConclusionEDM graphite is a critical material that is essential to a wide range of precision machining applications. Its superior thermal conductivity, electrical conductivity, and hardness characteristics make it an ideal material choice for manufacturers looking to improve their machining productivity without sacrificing quality.If you are looking for reliable and high-quality EDM graphite products, be sure to work with a reputable supplier known for delivering consistently excellent products and services.

Unveiling the Power of Ignot Molds for Graphite Mold Formation

Graphite Ignite Mold Revolutionizing Casting IndustryThe ever-evolving world of manufacturing has seen significant advancements in recent years, one of which is the development of the revolutionary Graphite Ignot Mold. (remove brand name) Combining cutting-edge technology with the expertise of a leading company in the field, this innovative solution is transforming the traditional casting industry, offering numerous benefits that were previously unimaginable.Casting has been a fundamental process in manufacturing for centuries. From the production of intricate metal components to the creation of larger industrial parts, casting allows for the mass production of objects with remarkable precision. However, conventional casting methods often face challenges such as product defects, high production costs, and extended lead times.Recognizing these limitations, (remove brand name) developed the Graphite Ignite Mold as a game-changing solution. The company has been a pioneer in the manufacturing industry for over two decades, continually pushing the boundaries of innovation. With their expertise and research, they have successfully revolutionized the casting process, improving efficiency, product quality, and overall productivity.The Graphite Ignite Mold, a highly specialized tool made from superior quality graphite, has become the cornerstone of this revolutionary casting technique. With its exceptional thermal conductivity and resistance to high temperatures, the mold ensures uniform heat distribution, reducing the likelihood of thermal stress and material defects. Additionally, the mold's ability to withstand extreme heat allows for faster solidification, resulting in reduced casting cycle times.One of the most significant advantages offered by the Graphite Ignite Mold is its versatility. Unlike traditional molds that are limited in terms of complexity and design, the graphite mold can accommodate even the most intricate geometries, enabling manufacturers to create highly customized components effortlessly. This flexibility makes the mold particularly appealing in industries such as aerospace, automotive, and electronics, where intricate designs are crucial for optimal performance.The introduction of this groundbreaking technology has transformed the casting process, significantly reducing the production costs associated with tooling and post-casting machining. By eliminating the need for complex tooling, manufacturers can save time and resources, resulting in substantial cost savings. Moreover, the high-quality surface finish achieved with the graphite mold often eliminates the need for additional machining processes, further streamlining the manufacturing timeline.A key aspect of (remove brand name)'s commitment to sustainability is the Graphite Ignite Mold's ability to be easily recycled. Unlike traditional casting molds that are often discarded after a single use, the graphite mold is designed to withstand multiple casting cycles. Once a casting is complete, the mold can be easily cleaned and reused, reducing waste and minimizing the environmental impact of the manufacturing process.The successful implementation of the Graphite Ignite Mold has garnered significant attention from the manufacturing industry and has given (remove brand name) a distinct competitive edge. With its combination of innovative technology, unmatched expertise, and cost-effective solutions, the company has established itself as a leader in the field, helping manufacturers across various industries overcome the challenges associated with traditional casting methods.Looking ahead, (remove brand name) continues to invest in research and development, constantly striving to improve their graphite mold technology. By collaborating with industry leaders, they aim to further optimize the mold's performance and expand its applications, ensuring that manufacturers can continue to benefit from the advantages offered by this groundbreaking solution.In conclusion, the emergence of the Graphite Ignite Mold has revolutionized the casting industry. With its ability to deliver unparalleled precision, reduced production costs, and sustainability, this innovative solution is paving the way for a new era of manufacturing. As (remove brand name) continues to drive advancements in this technology, the future of casting looks increasingly promising, with improved efficiency and endless possibilities for customization.

Custom Graphite Molds Supplier in China - High Temperature and Oxidation Resistant

Custom Graphite Molds - Perfect for Industrial UseIndustrial processes are diverse and require different forms of technology and machinery to achieve desired outputs. The production of quality products hinges on the use of high-quality tools and equipment. For this reason, industries invest a lot of time, effort, and resources in researching and developing new equipment and materials to meet the ever-increasing demand for high-performance machines. One such material that has proven invaluable in the production of industrial machines is graphite.Graphite is a form of carbon that has unique properties that make it ideal for industrial use. With its ability to resist high temperatures and oxidation, graphite has become the go-to material for producing molds of various shapes and sizes, which are essential in various manufacturing processes. At Hebei Well Carbon Imp and Exp Trading Co Ltd, we specialize in providing custom graphite molds to meet the specific needs of our clients.Custom Graphite MoldsCustomized graphite molds are products that are designed and produced to meet specific requirements of a customer. Every client is unique, and so are their production processes. Therefore, there is a need for custom molds to produce products that meet specific standards. At Hebei Well Carbon Imp and Exp Trading Co Ltd, we specialize in producing custom graphite molds that are designed to meet your specifications.Our custom graphite molds come in different shapes and sizes, making them perfect for different industrial needs. We can produce specialized molds that are designed to withstand high temperatures, oxidation, and other industrial processes. Our molds are made with high-purity graphite, which makes them strong and durable, ensuring long-lasting performance.Advantages of Custom Graphite MoldsCustom graphite molds offer several advantages that make them a popular choice among industries. These advantages include:1. Precision: Custom graphite molds are designed and produced to meet specific requirements, ensuring precision in production. This results in the production of high-quality products that meet specific standards.2. Flexibility: Custom graphite molds can be designed to produce different shapes and sizes of products, making them flexible to meet various production needs.3. Durability: Graphite molds are made with high-purity graphite, making them strong and durable, ensuring long-lasting performance.4. Cost-effective: Custom graphite molds are cost-effective in the long run since they are designed to meet specific requirements, reducing the need for repeated molds.ConclusionCustom graphite molds are essential in various industries, especially in producing high-quality products that meet specific standards. At Hebei Well Carbon Imp and Exp Trading Co Ltd, we specialize in producing custom graphite molds that are designed to meet our clients' specific needs. Our molds are made with high-purity graphite, ensuring long-lasting performance, and are cost-effective in the long run. Contact us today for your custom graphite mold needs. Keywords: China graphite mold, custom graphite molds.

Manufacturer of High-Quality Carbon and Graphite Rods and Blocks for Industrial Applications

NAC Carbon Products, a leading manufacturer of carbon and graphite rods and blocks, has announced that it is expanding its product line to include new grades of materials equivalent to the carbide graphite group. The expansion is in line with the company's commitment to providing high-quality products that meet the evolving needs of its customers.Founded in 1956 as National Carbon Company, NAC Carbon Products has a long history of providing custom-made carbon and graphite components for a wide range of applications. From automotive to aerospace, from industrial equipment to medical devices, the company's products have gained a reputation for their durability and performance."We take pride in the quality of our products, and we are constantly looking for ways to improve them," said John Doe, the CEO of NAC Carbon Products. "Expanding our materials portfolio is one way to do that. By offering new grades of carbide graphite, we can provide our customers with more options and help them achieve better results."Carbide graphite is a group of materials that offer excellent combination of strength, hardness, and thermal conductivity. They are widely used in high-performance applications such as cutting tools, dies, and molds. NAC Carbon Products' new grades of carbide graphite rods and blocks are designed to meet the specific requirements of these applications, offering superior resistance to wear, deformation, and thermal shock."We have worked closely with our suppliers and customers to develop these new grades of carbide graphite," said Jane Smith, the Sales Manager at NAC Carbon Products. "We have tested them extensively, both in our own facilities and in the field, and we are confident that they will deliver the performance and reliability that our customers expect."The new grades of carbide graphite rods and blocks are available in a variety of sizes and shapes, and can be custom-made to meet specific requirements. They can be machined, drilled, and fitted with inserts and other features, making them highly adaptable to different applications."Customization is our specialty," said Smith. "We have a team of engineers and technicians who are experts in carbon and graphite materials, and who can work closely with our customers to design and manufacture components that are tailored to their needs. Whether it's a large-scale project or a small prototype, we are committed to delivering the best solution."NAC Carbon Products' expansion into the carbide graphite market is part of a broader strategy to diversify its product line and strengthen its position in the industry. The company is investing in new equipment and technologies, and is expanding its global reach through partnerships and alliances."We are confident in the future of the carbon and graphite industry," said Doe. "There is a growing demand for materials that offer exceptional performance in harsh environments, and we believe that our expertise and innovation will be key to meeting that demand. Our new grades of carbide graphite are just one example of how we are pushing the boundaries of what's possible."NAC Carbon Products is a privately-owned company that employs over 200 people worldwide. Its headquarters and main production facilities are located in Cleveland, Ohio, USA, with additional offices and warehouses in Europe and Asia. The company is ISO 9001-certified and follows strict quality control procedures to ensure that its products meet the highest standards."We are proud to be a leader in the carbon and graphite industry," said Doe. "We are dedicated to providing our customers with the best possible products and services, and to contributing to the advancement of science and technology. We believe that our new grades of carbide graphite will help us achieve those goals, and we look forward to seeing the impact they will have on the industry.

How Graphite-Based Materials Are Changing Industries

Graphene Made Of Breakthrough: Unlocking the Potential of Graphene Utilizing Advanced Manufacturing TechniquesWith a vision to revolutionize the materials industry, a leading company in the field of advanced materials has announced a groundbreaking innovation — a new type of graphene made using advanced manufacturing techniques. This breakthrough in materials science is set to unlock the true potential of graphene and bring us closer to a future filled with incredible possibilities.Graphene, a two-dimensional material composed of a single layer of carbon atoms, is renowned for its exceptional properties. It is the thinnest and strongest material known to mankind, with extraordinary electrical and thermal conductivity. However, despite its potential for various applications, widespread use of graphene has been hindered by challenges in its manufacturing processes and the high cost associated with its production.Recognizing these constraints, the research and development team at {Company Name} embarked on a journey to revolutionize the production of graphene. Through their tireless efforts, they have successfully developed an innovative technique that allows for the large-scale manufacturing of high-quality graphene at a significantly reduced cost compared to traditional methods.This revolutionary graphene production technique leverages the advantages of a proprietary manufacturing process, ensuring the utmost control over the quality and characteristics of the material. By carefully optimizing the growth conditions of graphene on a metal catalyst, the team at {Company Name} has achieved unparalleled uniformity and high crystallinity in the final product.The implications of this breakthrough extend to various industries, including electronics, energy, aerospace, and healthcare. In the electronics sector, graphene promises to revolutionize the field of transparent conductive films, enabling flexible and foldable touchscreens, ultrafast transistors, and high-capacity batteries. Its exceptional thermal conductivity also holds great potential for enhancing the efficiency of electronics by improving heat dissipation.Furthermore, the aerospace industry will benefit from graphene's remarkable strength-to-weight ratio, which could enable the development of lighter and more fuel-efficient aircraft. Graphene has the potential to be used in the construction of advanced composites, leading to stronger and more durable materials for aircraft structures.In the energy sector, graphene's high electrical conductivity could pave the way for the development of next-generation solar cells and batteries. Not only could graphene improve the efficiency of solar panels by enhancing charge transport within the device, but it could also revolutionize energy storage by enabling faster-charging batteries with higher energy densities.The medical field also stands to gain from this breakthrough. Graphene's exceptional biocompatibility and electrical properties open up new avenues for applications in biosensing, drug delivery, and tissue engineering. Its high surface area-to-volume ratio allows for maximum interaction with cells, making it an ideal candidate for targeted drug delivery systems. Additionally, graphene-based biosensors could revolutionize diagnostics through their ability to detect a wide range of diseases with high sensitivity.The development of scalable manufacturing techniques for high-quality graphene is a significant achievement that will shape the future of numerous industries. By overcoming traditional manufacturing constraints and reducing costs, {Company Name} has taken a massive step forward in unlocking the full potential of graphene.With this breakthrough, the company aims to collaborate with industry partners and researchers to accelerate the adoption of graphene-based solutions. By providing access to high-quality and cost-effective graphene, {Company Name} envisions a world where the extraordinary properties of this remarkable material can be harnessed to propel us into a future filled with innovation and possibilities.As the demand for sustainable and advanced materials continues to rise, the announcement of this graphene breakthrough brings hope for a brighter and more technologically advanced future. The era of graphene-based technologies is upon us, and {Company Name} is leading the charge towards unlocking the full potential of this remarkable material.

Creating Perfect Gold Castings with Graphite Moulds

Graphite Mould for Gold Casting: The Ultimate Choice for Jewelers and GoldsmithsJewelry making has been an essential part of human culture for centuries. Gold, in particular, has been used as a symbol of wealth and prosperity. The process of casting gold jewelry involves melting gold and pouring it into a mold to give it a desired shape and size. But, the traditional method of using plaster of Paris or clay molds has proved to be time-consuming and inefficient. This is where the graphite mold for gold casting comes into play.Graphite molds for gold casting are highly durable, cost-effective, and widely used by jewelers and goldsmiths worldwide. The unique properties of graphite, such as its high melting point, non-wetting surface, and resistance to thermal shock, make it a perfect choice for casting gold. The use of graphite molds for gold casting has revolutionized the jewelry industry by simplifying the casting process and increasing the efficiency of goldsmiths.Graphite molds are highly versatile and can be customized to suit specific casting needs. They come in different sizes and shapes and can be used to create intricate patterns and designs. Moreover, they can withstand high temperatures, making them suitable for casting gold, silver, and other precious metals.One of the leading companies in the graphite mold industry is (company name removed). The company has been in the business for over 15 years and has become a trusted name in the field of graphite molds for gold casting. (Company name removed) offers a wide range of graphite molds that cater to the needs of jewelers and goldsmiths worldwide.The company's graphite molds are made of high-quality materials and are designed to meet the demands of the industry. Their molds are made to last and offer excellent performance, making them a great investment for businesses. Moreover, the company offers its customers a range of customization options, allowing them to create molds that are tailored to their specific needs.(Company name removed) has a team of highly skilled professionals who are committed to providing high-quality products and excellent customer service. The company's aim is to help its customers achieve their creative vision by providing them with the best possible solutions. They work closely with their clients to understand their needs and provide them with the right graphite molds that suit their needs.The company's graphite molds are highly durable, easy to use, and require minimal maintenance. They are designed to provide consistent results, making them a great investment for jewelry designers and goldsmiths. The molds are also easy to clean, helping to maintain their quality and durability.In conclusion, the use of graphite molds for gold casting has revolutionized the jewelry industry by simplifying the casting process and increasing the efficiency of goldsmiths. The availability of customized molds has further enhanced the versatility of graphite molds, making them suitable for creating intricate designs and patterns. (Company name removed) has become a trusted name in the industry, offering a wide range of high-quality graphite molds that cater to the needs of jewelers and goldsmiths worldwide. With excellent customer service and commitment to quality, (company name removed) is the ultimate choice for anyone looking to invest in graphite molds for gold casting.

Discover the Meaning of Crucible - a High-Temperature Heating Container

The Crucible: A Vital Tool for Melting GoldGold melting is a process that has been practiced by several cultures throughout history. It involves heating a substance, in this case, gold, to obtain a liquid state that can be easily molded into different shapes. The tool used for this process is called a crucible. In this blog, we will discuss what a crucible is and how it is used for melting gold.A crucible is a container made of metal or refractory material that is heat-resistant. It is often used in industrial applications such as metallurgy to melt and refine metals. Crucibles come in different sizes and shapes, with some being small enough to hold a few ounces of metal while others can hold several hundred pounds. They are also used in laboratories for scientific research.For melting gold, the crucible is heated with a torch or furnace until it reaches a high temperature that will melt the gold. The gold is then placed inside the crucible, and as it melts, impurities and other metals rise to the surface. These impurities are removed through a process called fluxing. Flux is a substance that is added to the crucible to combine with the impurities, making them easier to remove.One major benefit of using a crucible for melting gold is its ability to withstand high temperatures without melting or breaking. This is important because gold melts at a very high temperature of 1,064 degrees Celsius, and not many materials can withstand such heat. The crucible, however, is specifically designed to handle these extreme temperatures.Another advantage of using a crucible for melting gold is its durability. Refractory materials such as clay, graphite, and ceramic are commonly used to make crucibles because they are resistant to thermal shock, which can occur when a material is rapidly heated or cooled. This means that a crucible can be used repeatedly without cracking or breaking.In conclusion, the crucible is a vital tool for melting gold. It is designed to withstand high temperatures and is made from durable refractory materials. Crucibles are commonly used in industrial and laboratory settings and play a significant role in the production of various metals or alloys, including gold. If you are looking to melt gold, using a crucible is the best way to ensure a successful outcome.

Plastic and Glass Stirring Rods for Laboratory Use

Graphite Stirring Rods: The Key to Efficient and Effective Laboratory WorkLaboratory work is an essential aspect of scientific research and experimentation, and it involves a wide range of tasks and activities. One of the most important activities carried out in the laboratory is mixing and stirring different substances to create solutions, suspensions, emulsions, and other mixtures. For this purpose, laboratory technicians and researchers use various types of stirring rods, including plastic, glass, and graphite rods.In recent years, graphite stirring rods have become increasingly popular among laboratory professionals due to their unique properties and advantages. Graphite, a form of carbon, is an excellent conductor of heat and electricity, making it ideal for use in laboratory equipment. Graphite stirring rods are lightweight, durable, and highly resistant to corrosion, chemicals, and abrasion. They are also non-reactive and do not contaminate the substances being mixed, ensuring accurate and consistent results.The use of graphite stirring rods in laboratory work offers several benefits, including:1. Greater efficiency: Graphite stirring rods are highly efficient in mixing and stirring liquids, powders, and other substances. They have a smooth surface that reduces friction, allowing for faster and more thorough mixing.2. Improved accuracy: Graphite stirring rods do not impart any flavor, odor, or color to the solutions, ensuring accurate and reliable results. They are also easy to clean and sterilize, reducing the risk of contamination.3. Cost-effectiveness: Graphite stirring rods are more cost-effective than other types of stirring rods, as they have a longer lifespan and do not require frequent replacement.4. Versatility: Graphite stirring rods are versatile and can be used in a wide range of laboratory applications, from chemical reactions and sample preparation to food and beverage testing.When selecting a graphite stirring rod, it is important to consider the diameter, length, and shape of the rod. The diameter of the rod should be appropriate for the volume of the solution being mixed, while the length of the rod should be long enough to reach the bottom of the container. The shape of the rod can vary depending on the application, with common shapes including cylindrical, rectangular, and conical.In addition to graphite stirring rods, laboratory professionals may also use other types of stirring rods, such as plastic and glass rods. While these rods may be suitable for some applications, they lack the unique properties and advantages of graphite rods. Plastic rods are lightweight and disposable but may not be suitable for use with strong chemicals or high temperatures. Glass rods, on the other hand, are highly resistant to chemicals and high temperatures but may break easily and require careful handling.In conclusion, graphite stirring rods are an excellent choice for laboratory work due to their unique properties and advantages. They offer greater efficiency, improved accuracy, cost-effectiveness, and versatility, making them ideal for a wide range of laboratory applications. When selecting a graphite stirring rod, it is important to consider the diameter, length, and shape of the rod to ensure optimal performance and results. By choosing the right stirring rod for their application, laboratory professionals can ensure accurate, reliable, and efficient results in their work.

Unique Handmade Graphite Art Pieces for Sale - Shop Now

Graphite Pieces: The Perfect Addition to Your CollectionIf you're a lover of unique, one-of-a-kind pieces, then graphite is a material you'll want to add to your collection. Graphite pieces are handmade in various shops, with each artist presenting their unique set of skills in bringing these pieces to life. Graphite's unique properties make it an ideal material for making a variety of items, including jewelry, sculptures, and art.What is Graphite?Graphite is a crystalline form of carbon commonly found in metamorphic rocks. It is an excellent conductor of heat and electricity, making it a vital component in batteries, electrodes, and other electrical equipment. However, graphite has also found its place in the world of art and other creative endeavors due to its unique characteristics.Artists and designers use graphite as a material for creating unique and one-of-a-kind pieces due to its soft, malleable, and easily workable nature. The material can be molded, sculpted, or fashioned into various shapes, resulting in a wide range of beautiful art pieces loved by many. Graphite pieces are now gaining popularity among art enthusiasts, collectors, and jewelry lovers alike.Graphite Pieces - A Perfect Addition to Your CollectionWith its versatility, durability, and stunning appearance, graphite is the perfect material to add to your collection. Here are some graphite pieces that you can consider adding to your collection:Graphite JewelryGraphite jewelry is becoming more popular due to its unique and multi-dimensional appearance. From simplistic designs to intricate patterns, graphite jewelry pieces are handcrafted by talented artisans to create a unique and beautiful masterpiece. You can find an array of graphite jewelry pieces on Etsy, from earrings, necklaces, bracelets, and rings.Graphite SculpturesGraphite is ideal for sculptors to display their creativity and artistic talent. Graphite sculptures are frequently chosen for museums and art galleries. Sculptures can range from small, hand-sized figurines to life-size models. Graphite sculptures are truly unique in that no two pieces are alike, which makes them a true collector's item.Graphite DrawingsGraphite drawings have always been a popular form of art. Artists use different types of graphite pencils and tools to create a wide range of graphite drawings, from simple sketches to highly detailed masterpieces. Graphite is a versatile medium that allows artists to create images with varying degrees of nuance and texture.Graphite Home DécorGraphite pieces are not just limited to wearables and art. They can also be incorporated into your home décor. From unique graphite coasters to beautifully crafted graphite picture frames, the soft and subtle texture of graphite will bring an elegant and distinctive element to your home environment.In ConclusionGraphite pieces are perfect for anyone looking to add something unique to their collection. With its unique properties and versatility, graphite creates unique and original pieces, making it an ideal material for artists, designers, and creators. Whether it's jewelry, sculptures, drawings, or home décor, graphite pieces are perfect for anyone looking to elevate the aesthetics of their collection.